I’ve been into RC (remote control) cars, planes, helicopters,… for as long as I can remember. It’s a passion that I’ve shared with my Dad and now share with my son.

A couple of months ago I was doing some research on custom building a new RC plane. I came across a forum thread that was discussing laser cutting parts. That sounds pretty cool to me. I’d heard about home laser cutters a few years ago when a popular machine called the Glowforge was released. It was more than $2000 though, and that is way too expensive for a hobbyist like me.

After a bit more internet browsing, I stumbled on some discussions about K40 laser cutters that are cheap Chinese 40 watt laser cutters for less than $500. They definitely need some tweaking and fine tuning to work optimally though. “Cheap” and “tinkering”… sounds perfect to me! This is exactly exactly how I got started with 3D printing also.

After another month of thinking about it and shopping around, I found a really good deal on ebay for an open box deal. $250. I couldn’t pass it up.

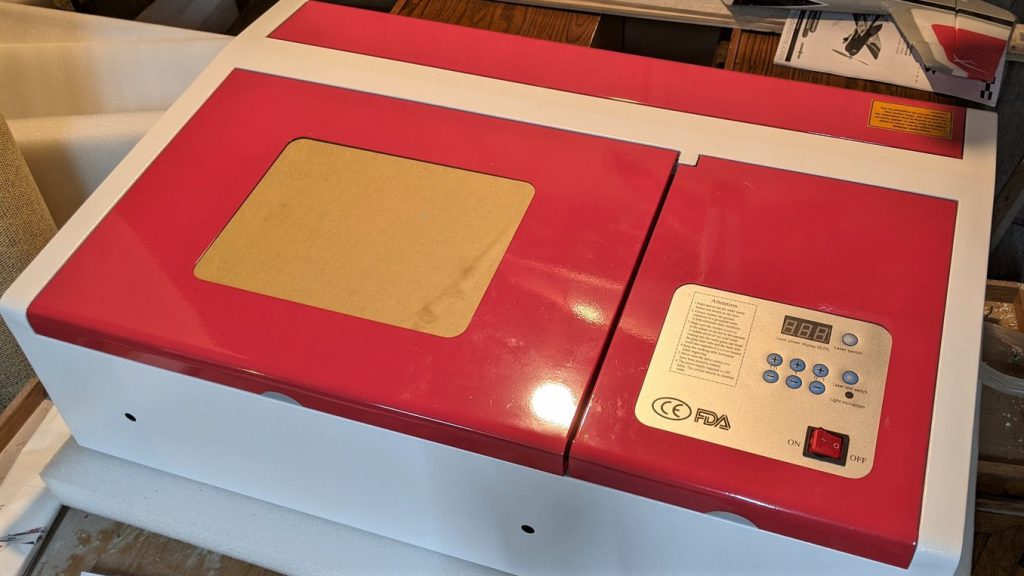

The laser cutter that I purchased is commonly called a full-size K40 with a digital interface. It has a 40W (max) CO2 laser tube and 8″x12″ cutting area. If you do a search on ebay for “40 watt CO2 laser cutter” you will find many similar offerings. This OMTech version on Amazon is also very similar.

A week after placing my order, the laser cutter arrived… and the fun began! Well… not right away. I needed to make some space for it, which resulted in a basement overhaul project first, but that’s a story for another day. Anyway, a couple of weeks later I fired up the laser for the first time.

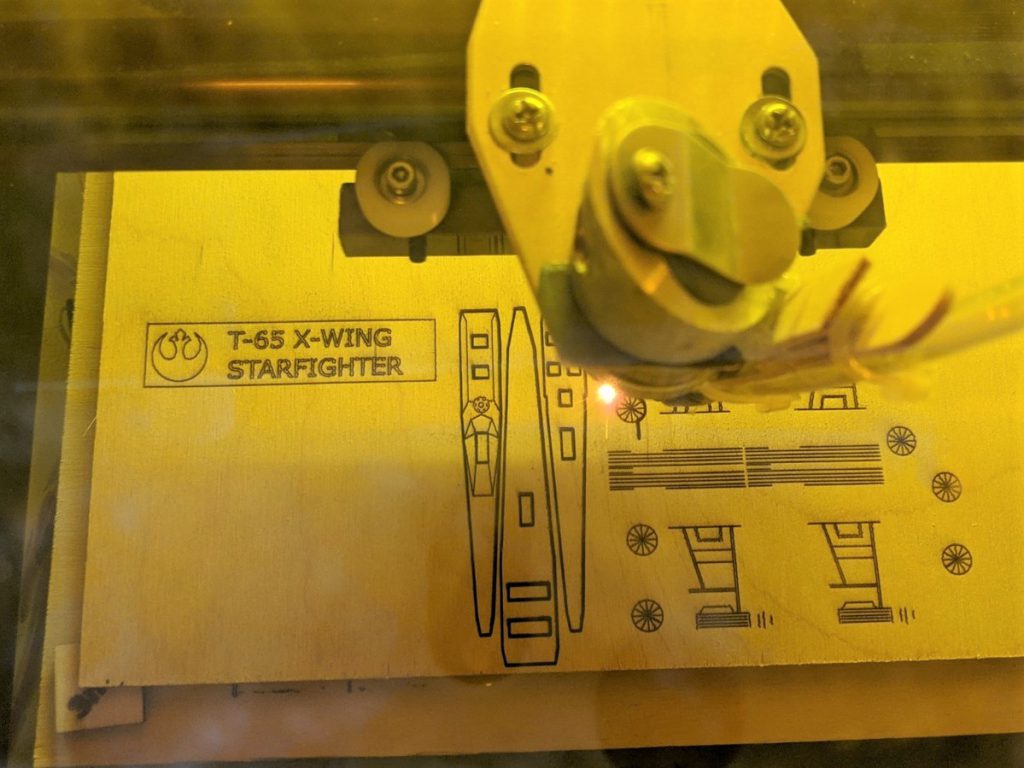

For the last month, I’ve been burning wood almost daily. This thing is fun and it is a pretty capable machine (after a little bit of tweaking). Reece has been learning a bit about designing, engraving, and cutting with me, so that has made for some good Father/Son time too.

Reece and I had a lot of fun designing and cutting some Christmas presents!

I’ll follow up with some info on the upgrades that I’ve made soon, but here is a little teaser for you…

- 40 watt digital laser cutter – purchased on eBay

- Exhaust fan and hose upgrade

- Air assist

- Analog current meter

- Cooling water temperature monitor

- Cooling water flow switch

- Proper grounding

- Door safety interlock switches

- Cutting bed modification

- Si Mirror upgrade

- Lens upgrade

[…] it out on the laser cutter was pretty straight forward. The only glitch for me was that my laser cutter is too small to fit the entire template. I solved that issue by dividing it up into (3) separate […]

[…] this article about my laser […]